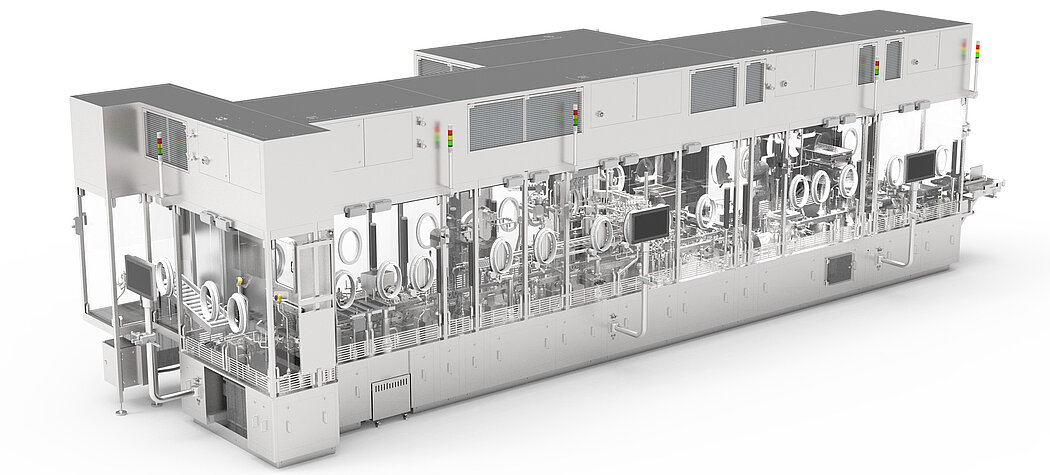

flexfill: Highest standards for safety and flexibility

Filling and closing machine for ready-to-use syringes, vials and cartridges

Our latest product line, flexfill, serves as the ideal solution for small to large pharmaceutical manufacturers, as well as Contract Development and Manufacturing Organizations (CDMOs) who need a reliable and flexible filling and closing machine for medium production volumes. Our standardized, qualified and validated machine concept offers you the flexibility you need, whether you want to process syringes, vials or cartridges.

Our modular machine concept ensures that 80% of the configuration is pre-defined and enables us to deploy and commission the system quickly, giving you the chance for a fast and easy qualification and validation. Choose from pre-configured modules to meet your individual requirements.

This not only leads to attractive delivery times, but also enables short time to patient requirements. We have taken the flexfill to a new level by combining our many years of experience in special machine design with a new mindset for off-the-shelf products.

FLEXIBILITY

With the flexfill, we offer a flexible solution that enables attractive delivery times without any loss of quality or compromises compared to complex customized machines. It is cost-effective, versatile and can be adapted to your requirements with our modular options.

PERFECTION

Many years of experience in special machine construction have made us experts, thanks to our collaboration with numerous customers from the pharmaceutical industry. All this expertise is combined in flexfill and has proven itself in practice.

Ready for rapid success? Then discover the world of flexfill!

Start production quickly:

Your benefits at a glance

- Short time to patient requirements due to modular design

- Design and qualification documentation available from day one to leverage your validation

- Individual customization options through a selection of pre-configured modules

- Compliant with all major regulatory requirements

Performance of the flexfill

All steps for processing syringes, vials and cartridges

Debagging

- No-touch transfer (NTT) for an aseptic transfer of ready-to-use containers to grade A

- Highest process reliability and safety due to automatic clamping and cutting

Opening

- Particle reduced opening of lid and liner due to infrared heating of the glue

- Disposal of the lid and liner to the outside of the containment/barrier

- Recognition of 1st air principle during opening of the tub

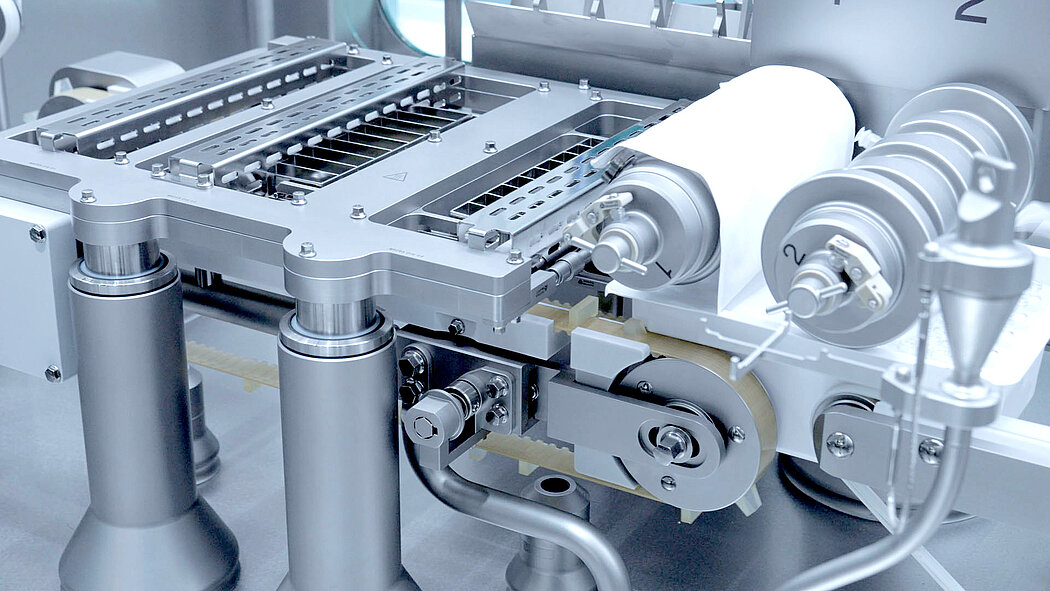

Filling and closing

- Flexible filling system (rotary piston and/or peristaltic pump filling technology)

- Highest effective output with In-Process-Control (IPC) for filling

- Possibility for gassing for oxygen sensitive products and vacuum for high viscous products, polymer containers or cartridges

- Sorting of closures in feeding tracks to eliminate the need for long lead time items like sorting bowls

- Camera systems for stopper presence and orientation for optimal reject handling

- Hygienic design for fast and easy cleaning operations

- Standard gassing and vacuum functions

Denesting

- Removal of single rejected vials, syringes and cartridges out of the tub

- Transfer Module with tub reject handling

- De-nesting of vials for downstream processing at sealing machine

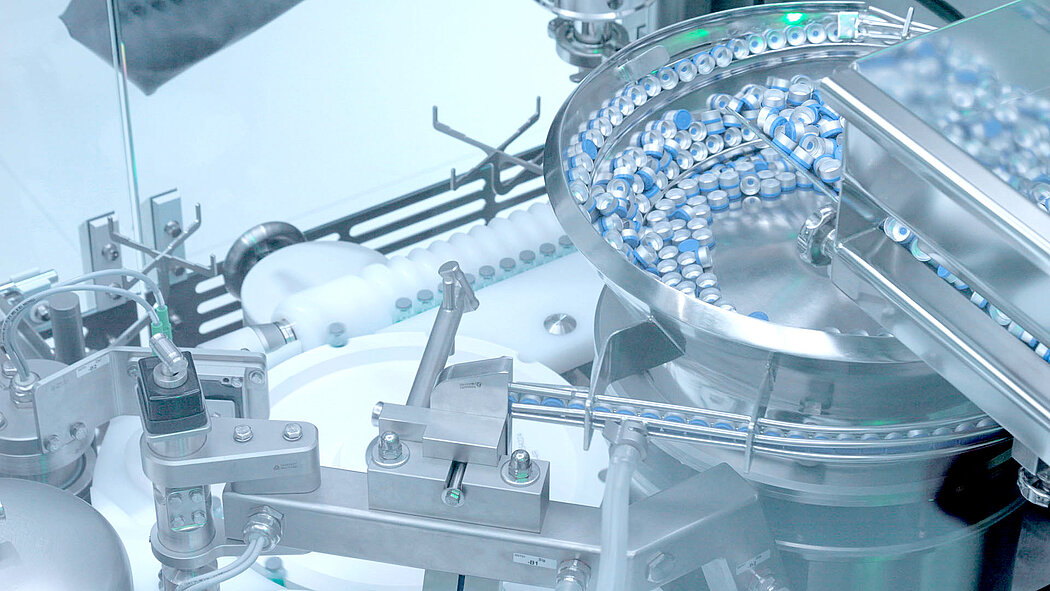

Sealing

- Camera system will be available soon to check the gap and presence of the stopper with a separate reject prior to the capping station

- Crimp quality control with camera tracking available

- Lowest particle generation during sealing due to groninger's high-end capping technology

Our partners for containment systems

SKAN

SKAN is a Swiss company and a global market and technological leader for isolators, cleanroom devices, and decontamination processes for the aseptic production of biopharmaceutical substances. SKAN’s core competency is the design and development of process isolators for the aseptic filling of biopharmaceutical products.

Franz Ziel GmbH

Franz Ziel GmbH stands for innovation, reliability and development in cleanroom technology. With more than 40 years of experience, they have constantly implemented new technologies and state-of-the-art product solutions. As a leading company in the sector of cleanroom technology, they operate globally for renowned companies.

![[Translate to English:] groninger Kontakt [Translate to English:] groninger Kontakt](/fileadmin/_processed_/e/6/csm_groninger-cta_6a20db86c5.jpg)