Press Releases

groninger at the CPHI – Our Heart is in Pharmaceuticals

It’s that time again! The who’s who of the pharmaceutical industry will congregate at CPHI, which will be held this year in Barcelona (Spain) from October 24 - October 26. The filling machine manufacturer groninger is also represented. On 80 square meters at stand 3T50, machine designs for the secure processing of extremely small and very small pharmaceutical quantities will be displayed.

Dirk Schuster, sales manager of the Groninger pharmaceutical division, talks about the importance of this trade fair: “In recent years, the CPHI has become one of the most important pharmaceutical industry events in Europe. The quality of the exchange about trends and their potential solutions or implementation is remarkable. “Everyone gets something out of it here – visitors and exhibitors alike,” says the 48-year-old with certainty.

At this year’s edition, groninger is focusing on the processing of small and very small pharmaceutical quantities because: “Their importance has increased significantly in recent years, both in pharmaceutical research and in manufacturing and processing,” says Schuster.

So-called “biotechs” have gained massively in importance in numerous areas of application - often on a patient-specific basis. This means that the genetic, molecular, and cellular characteristics of a patient or group of patients are taken into consideration throughout the manufacturing and processing of pharmaceuticals.

“These treatment methods are tailored to the individuals’ specific needs, allowing to make healthcare significantly more efficient. They are based on the possibilities that modern diagnostics, including genetic diagnostics, offer us today,” explains the sales manager.

A development that poses new challenges not only to the pharmaceutical industry itself, but also to the manufacturers of filling and packaging machines: In the past, for many years, the demand was primarily for lines for processing so-called blockbusters or lines that process frequently used medicinal products, such as vaccines, in large quantities quickly and affordable. Today, however, the demand is frequently for lines that can fill small and very small batches as safely and effectively as possible.

groninger adapted to this trend a few years ago and launched corresponding line formats, which the filling machine manufacturer presented at the CPhI.

Among other things, modules from the so-called labworx series will be shown. The entire filling and closing process can be carried out on the semi-automatic table machines. The special feature of these modules: The labworx series uses the same technologies, processing methods and components as in high-speed filling and closing lines by groninger. In this way, important insights and data gained during the development process can be quickly and easily scaled up to larger filling volumes and lines.

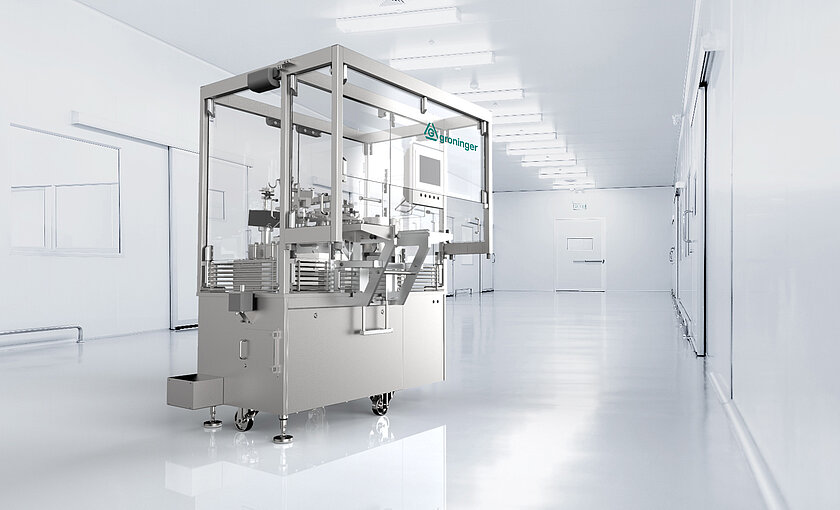

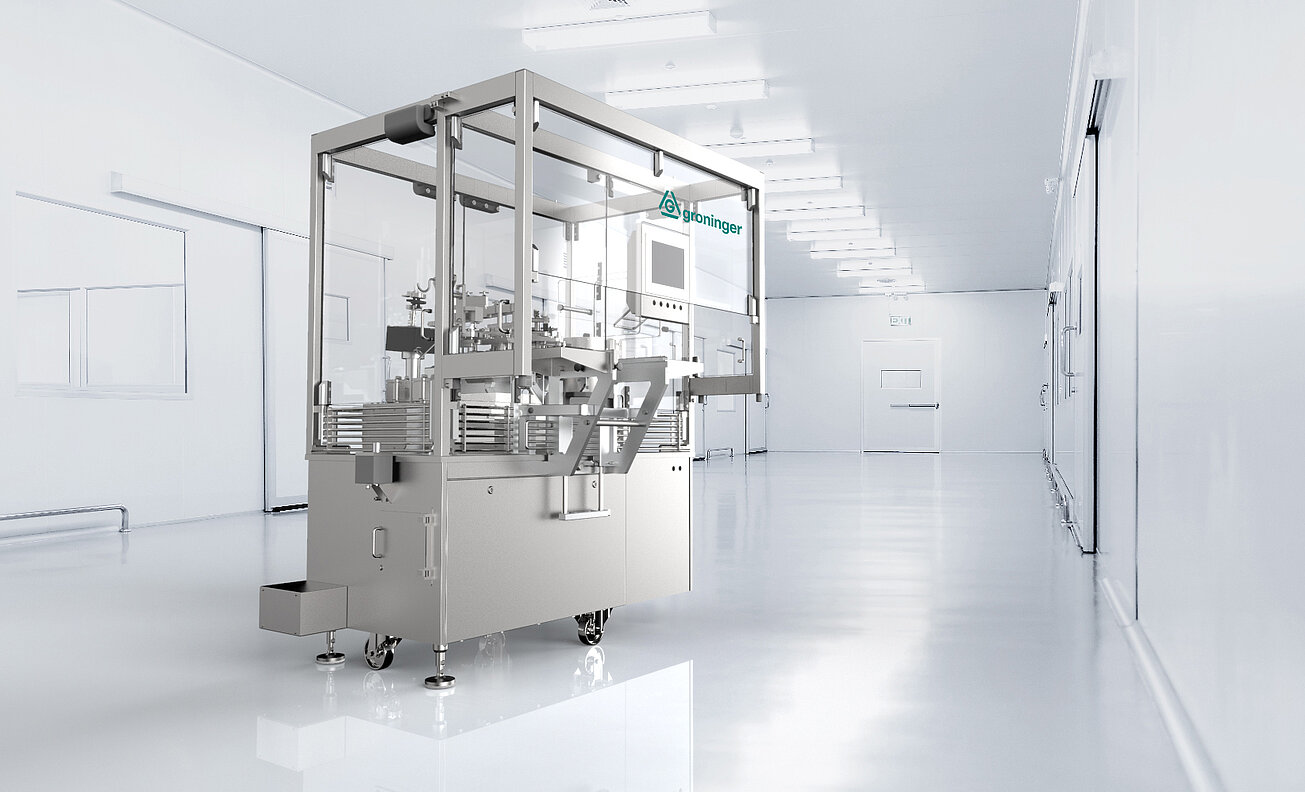

Furthermore, the compact system “DFVN1005V”, a filling and closing line for pre-sterilized objects in the nest for laboratories, test series and small batches, will be presented. Just like the labworx series, the DFVN also offers identical processes to those of a high-performance system. Here groninger relies on a mixture of manual handling and fully automated production areas: Automatic removal of the nest from the tub and placement in the centering frame or insertion and removal through a lockable opening in the machine protection are carried out manually. The transport to the filling and stopper insertion station and back again is fully automated. More than 10,000 items can be processed hourly on this line.

“With these exhibits we give an insight into what is already possible in the area of small and very small batches – without pharmacists having to compromise on the quality or safety of processing,” says Dirk Schuster, summarizing the advantages.